¿Con qué frecuencia se deben reemplazar los filtros BSC?

When it comes to biosafety cabinets (BSCs), the filter is one of the most crucial elements of the system because it plays a key role in ensuring that occupational safety requirements, the local environment, and indoor air quality are not adversely affected. The choice of filter, how long it will last, and how often it will need to be replaced are also some of the most important decisions when it comes to determining the life cycle cost of a BSC.

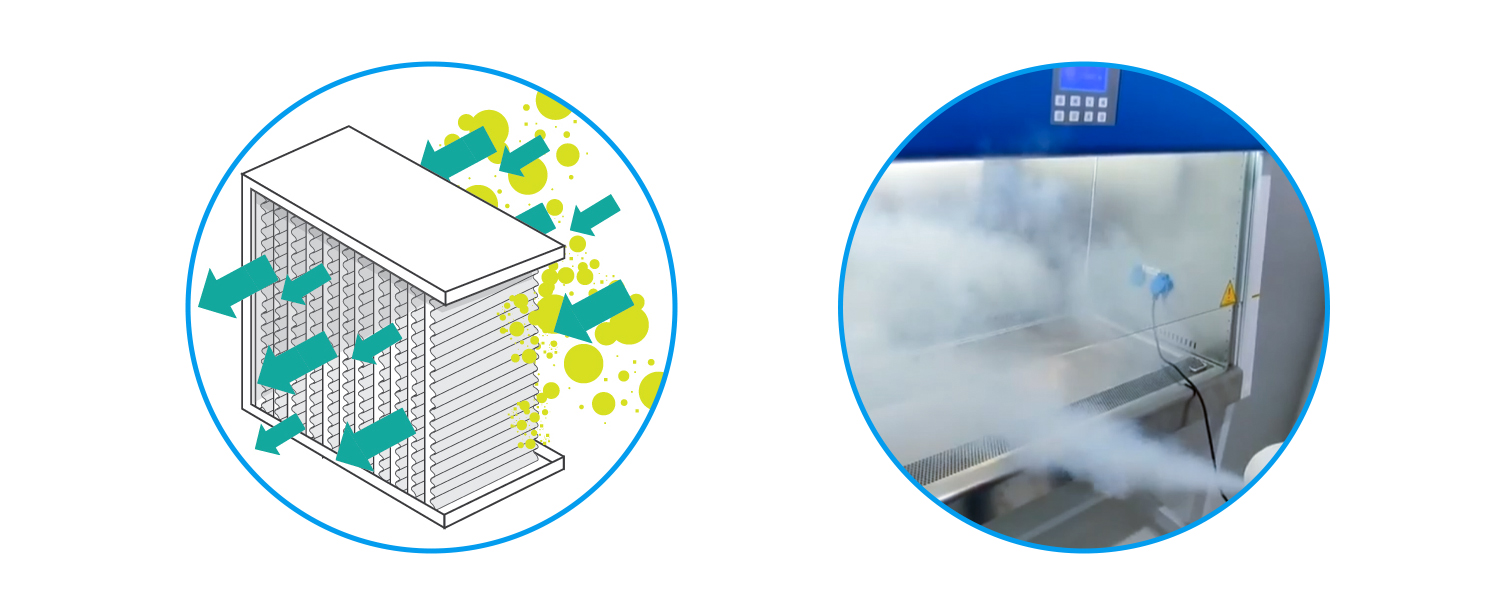

High Efficiency Particulate Air (HEPA) filters are the filter of choice for many BSCs and are regularly found in the most common class of BSC―the Class II BSC. HEPA filters are composed of a number of ultrafine fibers that collect particulate matter and remove it from the air. HEPA filters are very efficient systems and can trap up to 99.7% of particles that are 0.3 microns or smaller in diameter from the air and can be used to trap hazardous particles (including bacteria and viruses).

Understanding how a HEPA filter is going to behave and stay functional is key for ensuring safety and for costing purposes. However, knowing how long the filter is going to last is not a straightforward answer. There are a number of factors that can affect the lifetime of a HEPA filter and the filter life will be different depending on the laboratory environment that the BSC is used in. This means that the filter life will be different for each installation and could theoretically last forever if the conditions were right.

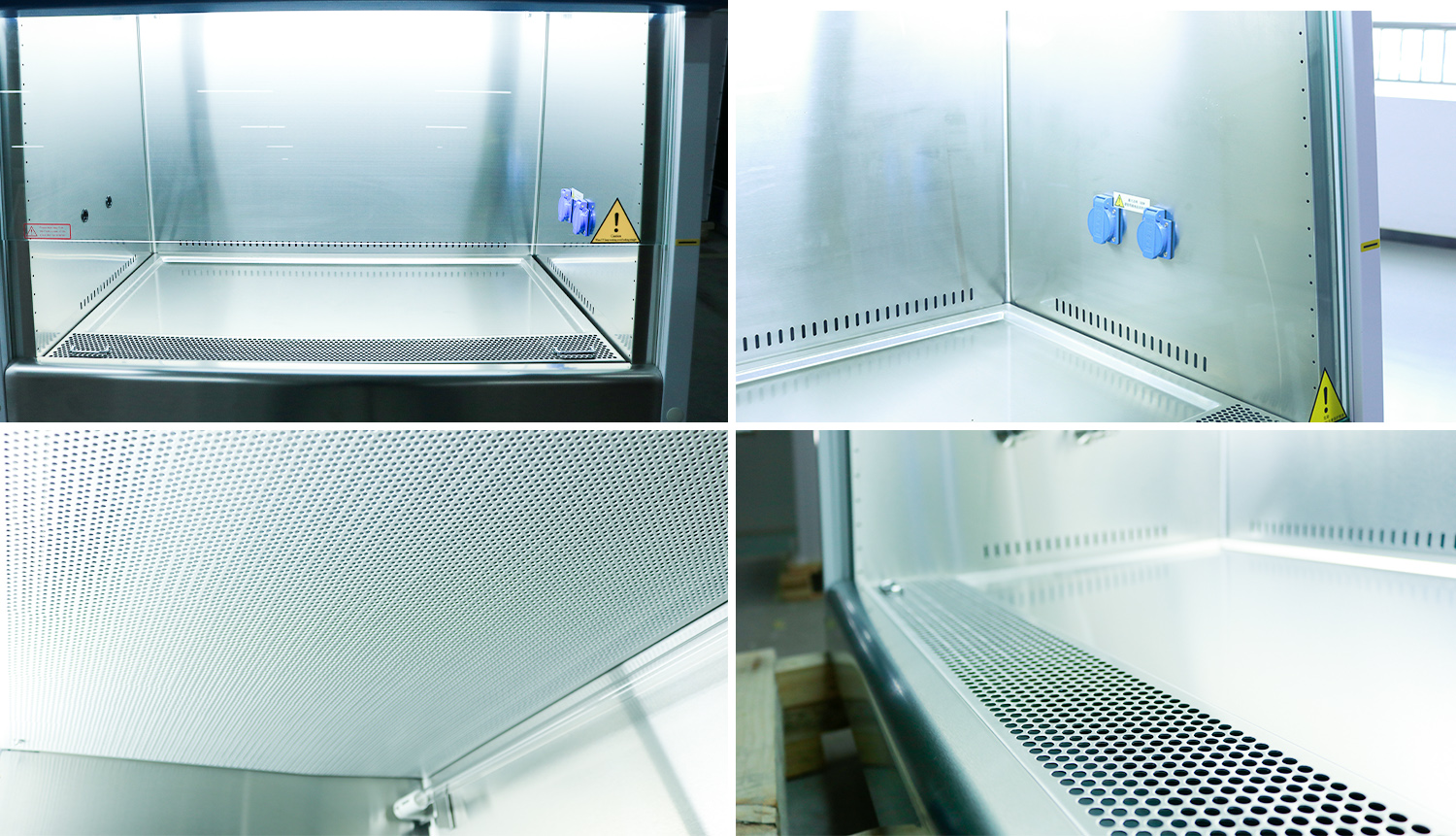

From a safety perspective, HEPA filters need to comply with NSF standards, and the filters need to be changed if the requirements of use―the NSF/ANSI 49 requirements―are not met for the BSC. The filters can be tested using aerosolized tests to determine a filter’s efficiency at specific sizes, but if the tests show that a BSC filter is not up to standard, then it will need to be changed. So, while this is a definitive way of determining if a filter needs changing, knowing what to expect in terms of filter changes before purchasing a BSC is a useful asset in the buying journey, as well as in the general upkeep of the BSC.

The Factors that Govern HEPA Filter Life

There are many factors that can affect and impact the useful life of a HEPA filter in a BSC. If a HEPA filter is installed in a clean room, it can theoretically last forever, but if it’s in an environment with lots of particulate matter, its lifetime is going to be much shorter. The average HEPA filter inside a Class II BSC typically lasts for around 7 years in a normal lab.

Over the years, there have been different certifications that have been put in place to determine the average lifetime of a HEPA filter. While the guidelines have changed over the years to fall in line with technological advancements, the guidelines continue to offer a baseline for what the lifetime of the filter should be.

Many of the areas that are considered for the specification involve the different airflows in the cabinet, the fan and motor performance in the BSC, the pressure drops inside the BSC, and the loading capacity of the filter itself (how much particulate matter can be held in the filter). All of these specification factors, especially the levels of particulate matter, the efficiency of the motor, the speed and delivery of the airflow, and the ability to withstand pressure drops inside the BSC, have an impact on how long a HEPA filter will last.

How Long Should a Filter Last?

There is no definitive answer for how long a filter should last. As previously mentioned, there are a number of factors that go into determining how long a filter should last. However, how much it is used and how much particulate matter is passed through it has a major bearing on whether a filter lasts for the theorized timeframe set out in the NSF specifications.

In a standard lab, 7 years is the average; this has been determined using the specifications in place and assumes that the BSC will not undergo more than a 10% decrease in total air delivery when there is a 180% increase in pressure drop/static pressure inside the BSC. However, the ability of a BSC air delivery system to withstand higher pressure drops without losing more than 10% air delivery can extend the usable life of the filter.

The baseline for the specifications uses a 10% decrease in total air delivery (as the maximum allowed airflow loss) to measure filter life, and the lowest measured pressure drop in the guidelines is 50%. If a BSC system can’t withstand a 50% pressure drop without losing more than 10% airflow, then it is not going to meet standard requirements. So, on the lower end, if a filter system is going to lose more than 10% air delivery at a 50% pressure drop, then the guidelines are that it will only last for around 3 years. This is why having a filter system that can withstand up to 180% pressure drop has now become industry standard.

On the other side, if the filter system can withstand a higher degree of pressure drop, while losing 10% or less air delivery, then the filter life can be extended beyond the average. For example, if you have BSC which can withstand up to a 250% pressure drop, then the filter is likely to last around 10 years instead of 7 (depending on particulate levels).

How well the BSC performs in this regard is primarily based around the motor design within the BSC and how efficient it is. So, how do you work out how long a filter will last for? There are tests that can determine the levels of pressure drop that a BSC can withstand. Taking this data and the motor design, a comparison can be made against historical data to give a rough idea of how long the filter will last. It’s not an absolute value, because the actual lifetime will depend on the filter loading, but it will give you an idea of whether it is likely to be 3 or 10 years that the filter will last―and if you’re trying to work out a life cycle cost of a BSC, then having a rough, but generally accurate, guideline of the filter life can be a useful asset.

How the Life of a Filter Can be Improved

As we discussed in the last section, the motor design has a big impact on the ability for a BSC to undergo a larger pressure drop and extend the filter life. The main way to improve the life of a filter above its standard design within a BSC is to employ a more efficient motor design. New motor technologies―such as DC ECM motors―are now becoming available to BSC users to, among other things, improve the life of the HEPA filter.

The newer DC ECM motors increase the load capacity and lifespan of a HEPA filter, and they also simultaneously reduce the energy consumption of the BSC compared to older motors―up to a 50% reduction. These DC motors don’t have an increased torque (so don’t improve loading capacity in this way like most motor advancements have), but they utilize airflow feedback loop control system or a motor feedback control system to increase the speed (in rpm’s) of the fan. These control systems and increased fan speeds can be used to reduce the filter loading capacity of the system, but the motor and blower can still meet the NSF requirements in terms of acceptable performance.

The DC ECM motor has a specific forward curved fan to fit the width of the BSC it is used in. The increase in filter loading capacity, thanks to an increased speed, means that the higher pressure drops (250%) are possible with these motors unlike many of the conventional motors used, allowing those longer filter lifetimes to be obtained. Out of all the motors used in BSCs, including older AC PSCs and other DC motors, the DC ECM has the lowest life cycle cost in terms of energy, filter load capacity and reliability.

Conclusion

There are no single answers to the questions “when should I change my filter?” and “how long will my filter last?” There can be a vast difference in HEPA filter lifetimes based on the level of particulate matter that will be exposed to the filter, the effectiveness of the motor used to provide the cabinet’s airflow and the level of pressure drop that a BSC can withstand without losing too much airflow performance.

However, having an idea―even if it is a rough one―of the realistic lifetimes of a HEPA filter (and how often you will have to change it) is crucial if you’re looking to work out the life cycle cost and value proposition of a BSC for your lab. Without it, you will be missing a key part of the costing when it comes to maintenance and part replacement.

Methods have been developed using these factors (in particular, pressure drop capabilities) to provide a rough estimate of a filter’s lifetime based on the performance of the motor within the BSC and the laboratory environment that the BSC will be utilized in. The average industry standard is around 7 years, but this can be as low as 3 years based on the lowest level of acceptable performance, or as high as 10 years if a new motor technology is used.